Vicat

Understanding Cement with Vicat Testing

In the world of construction, the quality and performance of cement are crucial for creating durable, high-strength structures. Vicat testing plays a key role in assessing these properties, ensuring that cement used in projects meets industry standards for consistency, setting times, and overall performance. This post takes a closer look at Vicat testing, exploring how it evaluates cement's behavior and why it’s essential for construction quality control.

Scroll down to read more information:

Three Key Vicat Tests

The Vicat apparatus is primarily used in three important tests: Consistency Testing, Initial Setting Time, and Final Setting Time. Consistency Testing (ASTM C187) measures the amount of water needed to create a cement paste with the right consistency to support optimal strength development. This test involves measuring penetration depth using a plunger; the target consistency is reached when the plunger penetrates 10 ± 1mm into the paste. The Initial Setting Time (ASTM C191) test determines when cement transitions from a liquid to a plastic state, providing a critical window for concrete placement. Final Setting Time (also ASTM C191) marks the point at which cement has hardened enough to hold its shape and support structural loads, allowing for formwork removal.

Factors Affecting Setting Times

Several factors influence cement’s setting times, impacting how quickly it transitions from a workable mix to a hard structure. Cement type, particle fineness, and chemical additives can accelerate or slow down setting times. Additional elements, such as sand content, ambient temperature, and water content, also play significant roles. Finer cement particles, for instance, generally lead to faster setting, while colder temperatures typically slow the process. By understanding these factors, construction professionals can make adjustments to achieve desired setting times, essential for timely project progression and structural integrity.

Methods of Vicat Testing

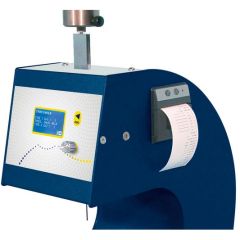

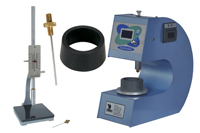

There are two main methods for performing Vicat tests: using a Standard Vicat Apparatus (Method A, ASTM C191) or an Automatic Vicat Apparatus (Method B, ASTM C191). The manual Standard Vicat Apparatus uses plunger and needle attachments to assess penetration depth over time, offering direct measurement but requiring regular monitoring. The Automatic Vicat Apparatus, on the other hand, streamlines the process, recording data automatically and providing higher accuracy and consistency. Vicat testing helps ensure that cement is ready for its intended applications, allowing professionals to make informed decisions on its suitability for construction projects.

Need Equipment?

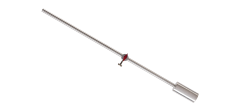

Searching for Vicat testing accessories? Forney has everything you need for cement penetration testing, including cone penetrometers, Vicat needles, plungers, Vicat glass plates, and much more. We even sell portable digital and analog pocket penetrometers, giving you the ability to perform penetration tests on the go.

Using an automatic Vicat apparatus is the best way to perform cement penetration tests. These devices can provide a controlled environment that produces reliable and repeatable test results on a regular basis. With Forney, you have a trustworthy partner to provide a Vicat penetrometer, machine, and needle, along with many other products and accessories.

If you have questions about which type of automatic Vicat apparatus is the right option for your cement penetration tests — or you need more info about the Vicat penetrometer, machine, and needle — contact Forney today and we can help.

-

-

- Modified Vicat Cone Penetrometer, 200 g for plaster

SKU: LA-4100-11

Modified Vicat Cone Penetrometer

- Vicat Apparatus, Time of Setting and Consistency (Hydraulic Cement Mortar)

SKU: LA-4100-12

Time Of Setting And Consistency Vicat Apparatus (Hydraulic Cement Mortar)

-

-

-

-

-

-

-

-

-

-

-